-

Shop All Products

-

-

Shop All Products

We meticulously sculpt and construct each model by hand to ensure our customers have durable shower units they can comfortably rely on for years to come.

-

-

-

About

-

-

About

We strive to be world-class in everything we do by hiring the best people, building the best product, and providing the best customer experience.

-

-

- Who We Work With

- Resources

- Projects

- 503-303-3300

- Contact Us

- Search Products

Blog

Discover the latest industry trends and insights related to bathroom architecture and ADA compliance.

What It Means to Be Handcrafted in Today's World

Think about how fast products are made, shipped, and received in today’s mobile economy. In a world dominated by e-commerce giants like Amazon and eBay, there’s something to be said for a shower manufacturer with a strict focus on service excellence — while also preserving the traditions and high quality associated with well-designed, handcrafted, artisanal products.

EverFab is one such company. Customer satisfaction and high-quality craftsmanship are our guiding principles, and our customers have come to see us as their all-important, trusted partner. That level of success doesn’t happen overnight; a solid and committed team with a storied history of success makes all the difference.

A Long-Established Reputation

With many years of experience, the committed and dedicated team at EverFab has been designing, innovating, manufacturing, and supplying well-manufactured fiberglass showers and shower units to contractors, architects, and senior living developers.

From material selection, traceability, and each stage of our production and assembly process, all the way to you receiving our product, every step is meticulously controlled to ensure the highest quality. For our customers, it means getting exactly what they need when they need it and always in good working order.

Extremely Durable, High-Strength Fiberglass Showers

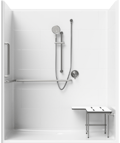

EverFab backs up this commitment to service excellence and high quality with shower units and accessories that are ANSI, ADA, and FHA compliant. However, for the artisans, craftspeople, and engineers at EverFab, it’s not enough to meet the basic standards and guidelines; pushing the envelope of design and engineering means exceeding these standards so customers receive the best walk-in showers available today.

We strive to perfectly demonstrate this ability by handcrafting showers that support twice the required weight of the 2010 Americans with Disabilities Act Standards for Accessible Design. It’s further backed by our unmatched 30-Year Warranty that guarantees all fiberglass showers will be defect-free and incorporate the highest levels of craftsmanship and quality.

It’s also demonstrated by the game-changing EverFab composite bottom plate. This revolutionary, pre-leveled, diamond-cut bottom plate addresses the biggest durability issue in the industry — bottom cracking — while reducing the need for mortar beds and trimming upon installation.

- EverFab shower units and accessories are ADA, FHA, and ANSI compliant.

- These durable shower units support twice the required weight of the 2010 ADA standards.

- Our pre-leveled, diamond-cut composite bottom plate tackles bottom cracking and cuts down on installation times.

High-Quality Craftsmanship Every Step of the Way

It’s one thing to talk about craftsmanship but another thing to back it up. EverFab’s core material creates a super bond, is 50 percent lighter than plywood, and is just as strong but has no moisture issues so common with plywood. This core material is typically reserved for fiberglass boats and wind turbine blades, making EverFab the only shower manufacturer in the industry to use it instead of plywood or cardboard.

It’s demonstrated by EverFab’s fiberglass layers, which contain more glass and less calcium sulfate. These are hand rolled to ensure a stronger cure with smoother handling. Gaps between layers are eliminated with a coating, and a final thick gel coat finish ensures no visible features can be seen or felt from the underneath layers.

Robust Packaging Solutions

For EverFab, craftsmanship and attention to detail don’t end with the finished product. It also extends to packaging. EverFab uses a proactive packaging process to ensure customers receive their fiberglass showers in good working order. This includes protecting the skirt, apron, and flanges with a well-crafted wooden enclosure.

It includes protecting lower-profile shower models with a wooden board at the back and using a diagonal board on five-foot showers for added protection. Warping, fading, or rotting is not a concern, even when stored outside for several months, since EverFab uses non-organic materials and perimeter-reinforced support structures.

- EverFab’s core material is 50 percent lighter than plywood, with a much better bond.

- EverFab’s hand-rolled fiberglass layers contain more glass and less calcium sulfate for a stronger cure.

- A thick coating eliminates gaps, and a final coat eliminates print-through.

- EverFab uses perimeter-reinforced support structures to ensure stable transportation.*

EverFab’s Simple Commitment to Its Customers

All EverFab fiberglass shower units are carefully designed, painstakingly crafted, hand-assembled, and thoroughly inspected. Our commitment to high-quality craftsmanship encompasses everything we design, make, and ship.

If an existing design doesn’t address your needs, we’ll design a customized solution for you. This is our commitment to you, our customers.

If you want to see how proactive and customer-centric we are, contact us now.

Get the latest!

Subscribe to our newsletter

Read On

Why EverFab Is Known For Making the Best Shower For Seniors

As EverFab CEO Dan Bryan put it, “We started EverFab with a vision that we would never compromise...Avoid Delamination with EverFab Commercial Shower Units

The commercial shower industry has a delamination problem. Heavy, cheap plywood backing is common...5 Benefits of a Fiberglass Shower Base

For senior living architects complying with ADA shower requirements, installation errors can be...9050 Porter Way SE, Aumsville, OR 97325

COPYRIGHT © 2025 EVERFAB