-

Shop All Products

-

-

Shop All Products

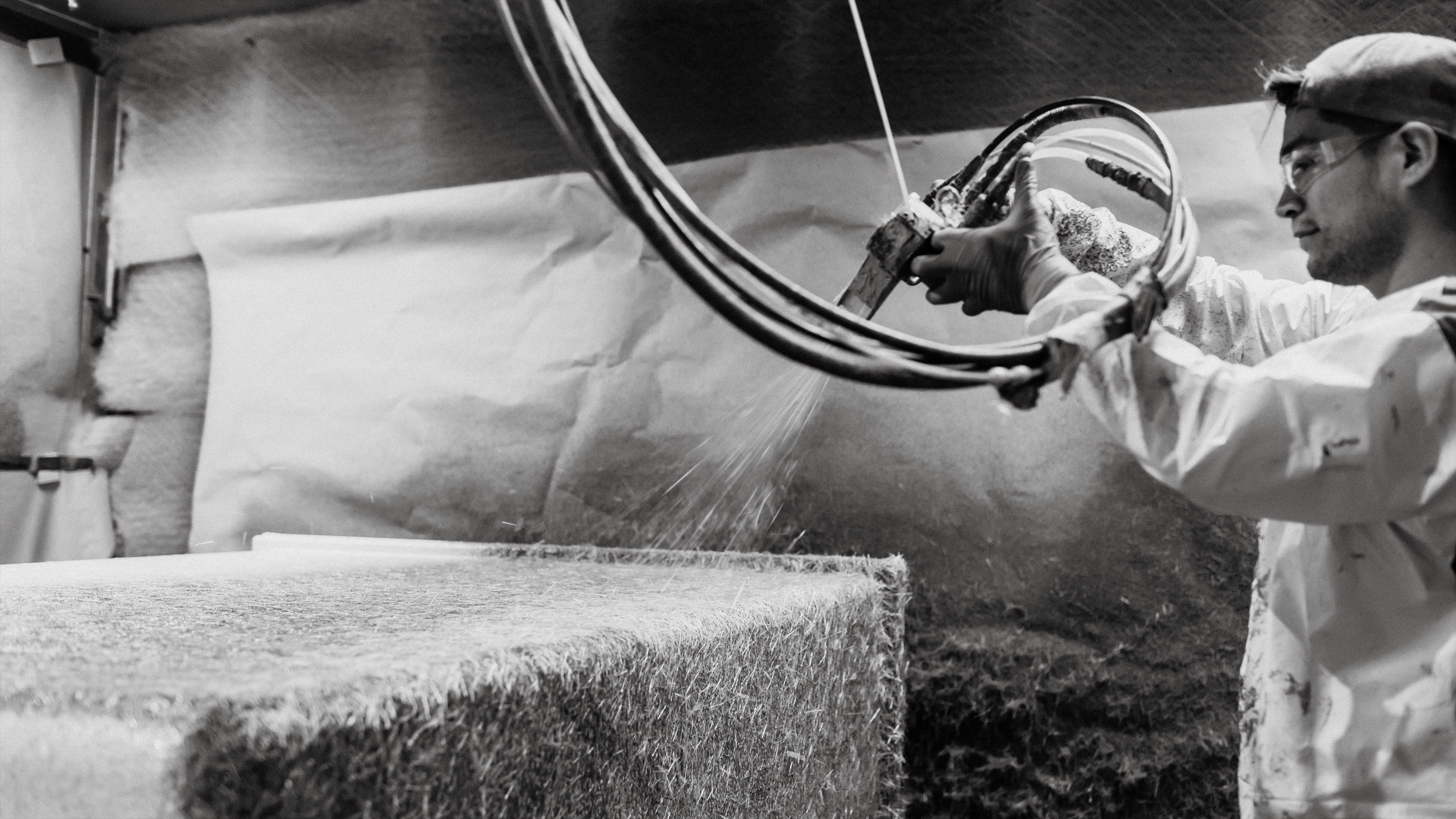

We meticulously sculpt and construct each model by hand to ensure our customers have durable shower units they can comfortably rely on for years to come.

-

-

-

About

-

-

About

We strive to be world-class in everything we do by hiring the best people, building the best product, and providing the best customer experience.

-

-

- Who We Work With

-

Resources

- Projects

- 503-303-3300

- Contact Us

- Search Products

Blog

Discover the latest industry trends and insights related to bathroom architecture and ADA compliance.

10 Considerations For Architects When Picking a Shower Manufacturer

Your choice of shower manufacturer may be the most impactful decision in a bathroom design. This is one reason that architects are often hesitant to work with new manufacturers. Instead, they’ll generally return to the companies they trust, time and again, until they come upon a project that their preferred manufacturers cannot serve.

Whether you’re hoping to start an ongoing relationship with a reliable shower manufacturer, hunting for the right partner to solve a particular design challenge, or simply surveying your options, here are ten things to think about while evaluating potential shower manufacturers for your project.

Table of Contents:

- Flexibility in Manufacturing

- Manufacturer Compliance With ADA, FHA, and ANSI

- Accessibility Options

- A Strong Base Support

- Downloadable Revit Files

- Acrylic vs. Gel Coat Finish

- One-Piece Units

- Material Composition

- Reliable Shipping

- Customer Experience

Picking a Shower Manufacturer? Consider These 10 Things:

Flexibility in Manufacturing

The ability to craft a custom solution to fit the precise needs of each project is a major advantage. Some manufacturers will produce shower models with inflexible measurements that always align with predetermined designs. The best shower manufacturers will not force you to settle for a unit that isn’t the right fit—or worse, to adjust your whole design to make one of their models fit—but work with you on a custom option that fits your needs.

Look for a shower manufacturer that produces their products internally (perhaps even by hand, as EverFab does). This gives the manufacturer the freedom to make small adjustments to their process or customize their products as needed. For instance, you may have a particular model in mind, but need it to be an inch narrower or wider than listed in their product brochure. Or perhaps you need to to come outfitted with grab bars or a recessed soap dish. The option to order a shower stall with special alterations can eliminate common frustrations of bathroom architecture.

Manufacturer Compliance With ADA, FHA, and ANSI

It’s always possible to cross-reference shower specs with code requirements yourself, but it’s much easier to work with a shower manufacturer that always guarantees full compliance. Make sure your manufacturer is experienced and knowledgeable with ADA, FHA, and/or ANSI standards (depending on the needs of your project), and takes them into account with the designs of every shower model.

ADA requirements for shower design, for example, will include specific standards for:

- Clearance

- Standing floor space (i.e., the size of the room)

- Controls and hand showers

- Thresholds

- Enclosures

- Water temperature

- Shower seats

- Grab bars (inside and outside the shower)

Keep in mind that each type of shower is subject to its own set of requirements, and certain types will have additional standards to meet. Roll-in showers must accommodate wheelchairs, whereas transfer showers will have precise requirements for load tolerance on pre-installed grab bars and shower seats (read more about ADA standards for these two types here).

Even traditional shower stalls or tub-showers should be designed for compliance and accessibility. Preferable shower manufacturers will either ship all units in a fully compliant form or with the ability to become compliant later on. This means every model should be properly reinforced for the future installation of grab bars or other accessories.

Accessibility Options

If you regularly work on bathroom architecture for senior living facilities, hospitals, or other public and private buildings that must prioritize accessibility, it pays to work with a shower manufacturer that has a broad selection of code-compliant accessories. Compliant metal grab bars, for example, can be selected to suit your particular design aesthetic in many unique looks and feels (U-shaped, L-shaped, straight, chrome, satin, stainless steel, flanged, unflanged, etc.). All shower accessibility options should never sacrifice code-compliance for appearance, however.

Some manufacturers will be able to ship you these products, but will not pre-install them in the factory. At EverFab, we can provide you with a versatile selection of fiberglass shower stalls that have the the accessories you need pre-installed. Even if you prefer your shower without the grab bar, seat, or shower unit pre-installed, all of our models are sufficiently reinforced to support future installation in the field at your convenience while remaining fully ADA compliant.

A Strong Base Support

The design of the shower’s base support system should always be your top priority when evaluating shower manufacturers. Bottom cracking, squeaking, and sagging over time are common issues in prefabricated shower units. In fact, a break in the bottom plate is the most frequent failure point in the industry.

This is partially due to the cost-effective but suboptimal way that many shower manufacturers support the unit base. PVC or wood legs attached to the back of the shower base can gradually distort, rot (or even break right off during transportation and installation), leaving the unit less than level or even entirely ineffective. Most installers realize this and compensate for the weak support by laying down a mortar bed beneath the shower floor. This adds strength, but it also adds time, labor, and expenses to installation. Foam reinforcement is cheap and fast, but not a strong supporting material. For a better bottom plate design, look for shower units with a one-piece composite that is fully laminated onto the units base and made with the same durable material as the rest of the shower body.

EverFab understands the value of this approach, which is why we’ve developed a more durable “bottom plate” than any other support system on the market. Our pre-leveled, diamond-cut bottom plate is made of a durable fiberglass composite with built-in legs that act as an extension of the unit’s base. Because it’s fully laminated onto the shower base, there is no risk of breaking, sagging, or rotting, as with PVC or wood-based designs.

Downloadable Revit Files

Nothing streamlines a shower manufacturer partnership like a collection of high-quality, free, and easily downloadable 2D and 3D Revit families. A catalog of instantly downloadable models makes it simple to browse and compare options, design custom solutions, and collaborate with the manufacturer on any bathroom architecture project.

Not all manufacturers have these files readily available, and of those that do, some will charge for access. At EverFab, we have decided to keep it simple and provide Revit families for all of our products entirely for free. We partner with BIMsmith and Bim Object to keep our comprehensive collection of Revit families available for download on their platforms as well as our own website.

Acrylic vs. Gel Coat Finish

Acrylic vs. Gel Coat Finish

Gel coat and acrylic are traditional choices for finishes in today’s shower units, and both are lightweight materials that make transportation and installation relatively easy. They’re popular due to their sleek, easy-to-clean finish and ease of installation compared to hefty, expensive, and time consuming ceramic, stone, or tile options. Both of them require fiberglass reinforcement resulting in a lightweight, easy to install shower.

But given a choice between an acrylic and a gel coat finish. which one should you go with? This will come down to the differentiators between the materials. Acrylic tends to be more expensive (anywhere from 25-50% more than gel coat), and if damaged, requires more costly and complicated repairs. A gel coat finish is more easily fixed or patched due to the workability of hand sprayed gel coats. Acrylic models can be tougher than their gel coat counterparts—largely because the material is usually thicker—but they’re also prone to brittle chips and weak spots around certain curves in the mold that may stretch the vacuum-pressed acrylic sheet too thin.

The uniformity and durability of a gel coat makes it ideal for commercial architecture projects. If your bathroom design anticipates rough usage, acrylic offers added strength but will be more cumbersome and expensive to fix in the event of damage.

One-Piece Units

Seamless, one-piece shower or shower-tub units offer several major advantages over stone or tile showers that must be painstakingly assembled and sealed. For starters, a one-piece shower is lightweight, making it quick and easy to transport to the project. Installation is equally fast and easy, and the seamless nature of the unit means it will have a perfectly reliably moisture seal from the surrounding architecture. Unnoticed gaps or leaks in multi-piece units can lead to mold, rot, leaks to lower floors, and even degradation of the support structure in the long run.

Ask any potential fiberglass shower manufacturer whether they offer one-piece shower stalls, or if some assembly will be required. Unless there’s some compelling reason to install the tub separately from the shower walls in a shower-tub unit, for example, you’re better served by choosing the shower manufacturer with a one-piece option.

Material Composition

The materials used to craft the shower will determine not only the aesthetics, but also the durability (and usability) of the unit. You may already know whether you’re interested in working with options made with ceramic, stone, acrylic, fiberglass, or something else, but even these categories can be further broken down into certain material makeups and qualities.

A fiberglass shower manufacturer, for example, will use both calcium sulfate and glass in the construction of their showers, but what is the ratio of calcium sulfate to fiberglass in their products? This can differ from one company to another, and it will impact the physical properties of the shower.

Calcium sulfate is required to reduce the flammability of the fiberglass, and the combination of heft and hardness that it gives to the finished product can make it appear more durable, too. However, a high concentration of calcium sulfate actually makes fiberglass much more brittle, leaving it prone to cracks, chips, and damage.

This is why EverFab has developed an optimized blend with a higher glass concentration (and less calcium sulfate than many competitors). Our carefully calibrated manufacturing process results in units that are lighter weight and more durable than other fiberglass showers. With EverFab, you know you’re getting a level of quality and reliability that’s not offered by shower manufacturers.

We’ve proven the strength of EverFab units with load-bearing tests by Carlson Testing Inc (CTI) on our ADA compliant shower model S3839A and ADA compliant tub shower model TS6032A. Both units more than double the strength standards set by the ADA, and in one test the grab bar was able to support as much as 1,500 pounds (well above the 250 pounds required by the ADA).

Reliable Shipping

Outside of the units themselves, safe and reliable shipping is likely to be a top concern of bathroom architects. It’s worth taking time to inquire about and evaluate the shipping process of each shower manufacturer that you have under consideration, rather than relying solely on the specs of their products to make your decision. Even the perfect tub or shower unit is of no value to a bathroom architect if it arrives damaged.

Worthy precautions to look for in the shipping process include:

- Installation of a wooden perimeter that surrounds the tub or shower stall and protects the skirt, apron, and flanges from potential damage.

- A strong, flat wooden board to prevent the drain or shower floor from resting on the ground directly (a common source of damage in transportation). This is even more critical on low-profile models.

- A diagonal board for additional structural integrity, especially on larger shower stalls.

Customer Experience

Only an experienced shower manufacturer can offer the expertise and versatility to reassure an architect that their products will fit perfectly and arrive on time. Newcomers to the industry will sometimes forgo some percentage of their profits to offer a reduced price point and break into the market. However, if they lack the equipment and knowhow to guarantee quality and reliability, these savings will be for nothing.

Our professional shower artisans at EverFab have more than 35 years of collective experience working as shower manufacturers. We constantly strive to optimize our equipment and provide our clients with the personalized, flexible, and efficient service they need to get the most from their architectural designs. The 30-year warranty that we place on all EverFab fiberglass shower units is a testament to the confidence we have in our craftsmanship.

If you’re interested in learning more about the EverFab Advantage, we’d love to talk. Get in touch with our team and we’ll be able to answer questions, consult with you on your needs, and make recommendations that will best serve your project.

Get the latest!

Subscribe to our newsletter

Read On

Strength-Testing is a Crucial Step Toward an ADA Compliant Shower

If you want to have an ADA compliant shower, you need to make sure the unit(s) you purchase are...The 5 Best Bath Qualities to Look For in ADA Compliant Showers

ADA compliance standards are important for ensuring reliable and accessible facilities, but the...How EverFab Manufactures the Best Bath Tub-Showers

At EverFab, we take quality seriously. Our team of professional bathroom artisans brings years of...9050 Porter Way SE, Aumsville, OR 97325

COPYRIGHT © 2025 EVERFAB