-

Shop All Products

-

-

Shop All Products

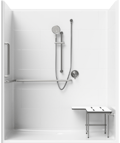

We meticulously sculpt and construct each model by hand to ensure our customers have durable shower units they can comfortably rely on for years to come.

-

-

-

About

-

-

About

We strive to be world-class in everything we do by hiring the best people, building the best product, and providing the best customer experience.

-

-

- Who We Work With

- Resources

- Projects

- 503-303-3300

- Contact Us

- Search Products

Blog

Discover the latest industry trends and insights related to bathroom architecture and ADA compliance.

The Best Bath Designs Feature Showers That Don’t Crack or Delaminate

The most concerning trend in the pre-fab shower industry today is the regular appearance of cracks, sagging, and damage to the shower bottom. It’s astounding how frequently this still happens, even in newer showers. How-to-guides are always popping up online (such as this one on wikiHow and this one on HomeAdvisor) to help folks patch, conceal, and otherwise deal with unfortunate damage to the bottom plate.

This is—paradoxically—both the most common failure point in a fiberglass shower and also one of the easiest failures to prevent. After all, it only takes a properly supported shower bottom to prevent this common experience. So why aren’t more companies producing showers that eliminate the risk of shower pan replacement or repairs?

The Bottom Support vs. The Bottom Line

Cost is a big factor for the manufacturer. It simply takes more deliberate architecture and time to manufacture the best bath designs or shower designs with high-quality materials. Most shower bottoms are supported either with cost-efficient but relatively weak PVC or wooden legs, or without any support whatsoever. In cases without pre-existing supports, a mortar bed and properly supportive base must be addressed during installation. This pushes the time commitment onto the contractor, not the manufacturer, and offers little protection for the unsupported shower bottom in transport.

The Drawbacks of Low-Cost Shortcuts

While cardboard backing, plywood, and PVC legs may be cheap and less labor-intensive materials for reinforcing a shower, the best bath designs will never use them because of the numerous drawbacks, including:

- The pure heaviness of the final unit. Wood-reinforced showers take multiple people to maneuver and install.

- Swelling and distortion when wood or cardboard are rained on in a wholesale yard or job site.

- Poorer bonding of fiberglass layers, which can lead to separation, peeling, and delamination.

- Warping and waving in the fixture walls or sagging in the floor over time.

- Cracking in the poorly supported shower bottom.

Quality Showers Will Use Quality Materials

It’s possible to avoid all of these drawbacks with carefully designed showers that make better use of the best bath and shower material in the prefab market: fiberglass. Our EverFab Core Material reduces the final fixture’s weight by 50% vs. plywood-backed shower units and provides the same strength that other industries rely upon to reinforce boat hulls, wind turbine blades, and other heavy duty products.

Every layer is fine-tuned for optimum strength and durability, from the gel coat down to each layer of fiberglass, spray core, and core material. The EverFab Core Material provides extreme strength and helps each layer to chemically bond, while our fiberglass is formulated with a higher glass-to-calcium sulfate ratio for added strength and hand-rolled by expert bathroom artisans with extreme care.

The Best Bath Designs Need a Better Bottom. We’ve Got It.

Quality materials are key, but the shower bottom also needs proper reinforcement. This should never be left up to the contractor to solve, and a few flimsy legs will never protect a shower through years of use.

This is why every EverFab shower bottom features a better, more durable shower pan than anything else in the fiberglass shower industry. Our one-piece, pre-leveled, and diamond-cut bottom plate design is fully laminated directly to every unit’s base, which eliminates the risk of cracking, sagging, or delaminating over time (as wood and PVC designs are prone to do).

Get in touch with us today to learn more about the EverFab Advantage and how our showers can protect your project through shipping, assembly, and many years of use.

Get the latest!

Subscribe to our newsletter

Read On

5 Ways EverFab Protects its Fiberglass Shower Units During Delivery

The most dangerous period of time for fiberglass shower units is the window between departure from...Avoid Delamination with EverFab Commercial Shower Units

The commercial shower industry has a delamination problem. Heavy, cheap plywood backing is common...How EverFab Manufactures the Best Bath Tub-Showers

At EverFab, we take quality seriously. Our team of professional bathroom artisans brings years of...9050 Porter Way SE, Aumsville, OR 97325

COPYRIGHT © 2025 EVERFAB